Industrial Handle:

An industrial handle is a professional tool for the development of industrial equipment. It is used to assist in the operation, control, or movement of industrial equipment, medical equipment, commercial equipment, appliances, boxes, etc. Industrial handles are typically made of metal, plastics, or synthetic materials. Different materials are used for industrial handles based on the specific application scenarios. Industrial handles come in various structures and types, including pull type, folding type, and embedded type, to cater to different scenarios and installation conditions.

What are the materials used for industrial handles? What are their advantages?

Usually, the industrial handle materials commonly seen in the market include stainless steel, aluminum alloy, plastic, rubber, and cast iron. Each of these materials offers distinct advantages.

Stainless steel is suitable for a variety of harsh environments due to its corrosion resistance, high strength, and wear resistance.

- Aluminum Alloy: Lightweight, high strength, corrosion resistance, and excellent processing performance.

Zinc alloy: Casting performance is good, as it can be molded into various complex structures with surface treatment effects.

Plastic materials such as nylon, polypropylene, etc., offer good insulation, corrosion resistance, and lower cost.

Rubber provides a good grip feeling, with certain shock absorption and anti-slip performance.

- Cast iron: It has high strength, but it is heavier. It is commonly used in situations that require higher strength.

What are the surface treatments for industrial handles?

Common surface treatments for industrial handles include electroplating, painting, oxidized treatment, polishing, frosting, powder coating, and electrophoretic coating. Various surface treatments are chosen based on specific requirements in different situations.

What are the precautions for buying industrial handles?

When buying industrial handles, it is important to consider various factors. In this guide, we will introduce you to the relevant considerations.

- The choice of material: Depending on the environment of use, it is necessary to purchase different materials. For instance, if the handle will be used outdoors for an extended period, stainless steel industrial handles can be considered.

- Load capacity varies depending on the product. Choose the appropriate industrial handle based on the load requirements when making a purchase.

When installing the product, make sure to purchase it to ensure compatibility with your equipment and convenient installation.

When selecting a brand, quality is paramount. Opting for a reputable manufacturer is crucial as their strength typically ensures higher quality standards.

- After-Sales Service: It is important to understand the supplier’s after-sales service policy to safeguard your purchase. Ensure that maintenance support is provided during the warranty period.

- Sample Test: If the supplier can provide a sample test, then we can assess the performance based on the sample provided.

How to Judge the Quality of Industrial Handles

During material inspection, observe the appearance for defects, cracks, air holes, or impurities. High-quality products should have a uniform and smooth surface.

Strength test: Use mechanical equipment to test the load and determine if it meets our requirements.

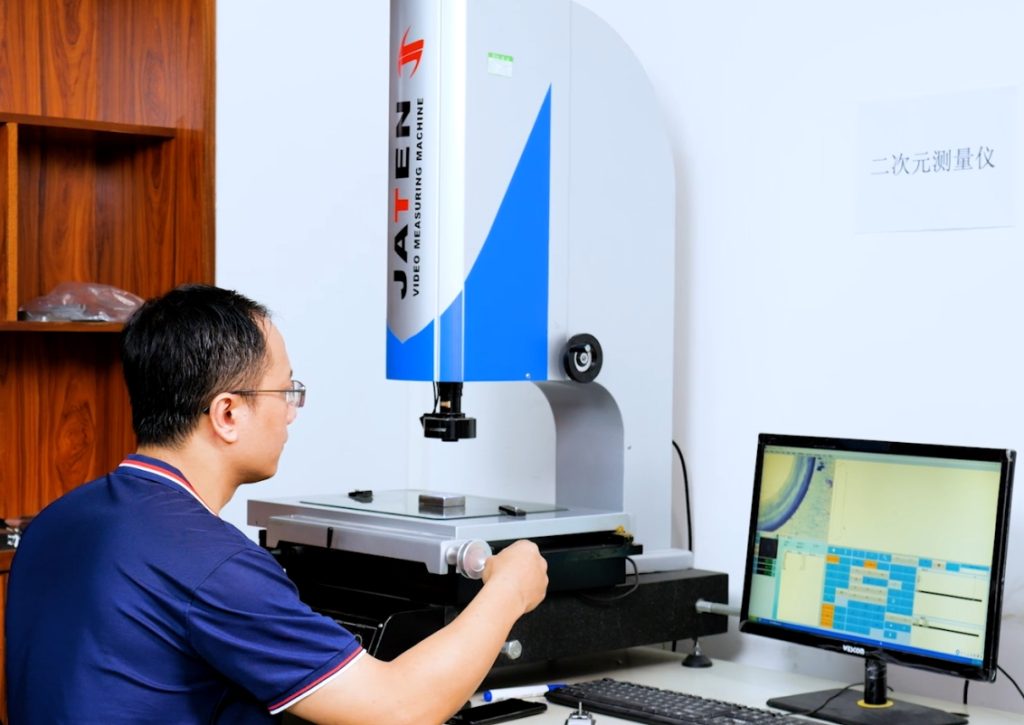

- Size and dimensions are verified using measuring instruments to ensure they meet the required specifications, including length, width, thickness, etc.

Corrosion resistance is tested using a salt spray tester to determine if the product meets the necessary standards.

When it comes to brand and certification, well-known brands typically have a superior quality control system, such as ISO standards.

About Haisepu manufacturers, we have 9 years of R & D and production experience in the field of industrial parts. In addition to industrial handles, we also offer hinges, torque hinges, door locks, latches, and other industrial accessories. For information about industrial handles, please contact us.

logo

logo