The Dual Axis Torque Hinge is a hinge type with a unique design and a wide range of applications. It offers a flexible, stable, and customizable opening and closing solution for various equipment and products by utilizing two axes and allowing torque adjustment. Below is a detailed overview of the Dual Axis Torque Hinge.

I. Features of Dual Axis Torque Hinge

Dual-axis design

Compared with traditional single-axis hinges, the dual-axis design increases the flexibility and stability of movement. The two axes can work in tandem, allowing the connected components to rotate and position themselves in more complex directions.

Torque Adjustment

The amount of torque can be adjusted according to actual needs, thus controlling the force of opening and closing and the position of the parts to be held. This allows the two-axis torque hinge to adapt to different weights, sizes, and usage scenarios.

High precision and durability

High-precision manufacturing processes are usually adopted to ensure the rotational accuracy of the shafts and the tight fit between the components. Simultaneously, high-quality materials, such as high-strength metals or engineering plastics, are used to provide excellent durability and wear resistance.

Compact structure

Despite the dual-axis and torque adjustment functions, the structure of dual-axis torque hinges is usually compact, enabling complex motion control in limited space.

II. Application Areas

Electronic devices

Screen connection parts of laptop computers and tablet PCs enable multi-angle flipping and stable positioning of the screen to meet various usage needs.

The folding mechanism of a cell phone provides a reliable folding and unfolding function while ensuring the stability of the screen at different angles.

Medical Equipment

Adjustable parts of surgical instruments, such as lighting equipment or camera mounts, facilitate doctors in performing precise operations during surgery.

Articulated parts are used for medical beds and wheelchairs to allow for angle adjustment and fixation of bed and wheelchair components.

Industrial equipment

Articulated joints for robot arms enable robots to perform tasks precisely in complex work environments.

Workholding fixtures are essential for automated production lines to ensure the accurate positioning and rotation of workpieces during machining.

Furniture

Adjustable desks and dining tables allow the angle and height of the tabletop according to their needs.

Connecting components of folding furniture, like folding chairs and folding beds, ensure stable folding and unfolding mechanisms.

Points to Consider When Choosing a Product

Torque Range

Select a dual-axis torque hinge with a suitable torque range based on the weight and size of the equipment or product being applied. Ensure that the torque meets the opening and closing needs of the component without being too large and causing operational difficulties.

Accuracy and Stability

Understand the manufacturing process and accuracy level of the hinge, and select a product with high precision and stability to ensure long-term reliability.

Material and Durability

Give preference to dual-axis torque hinges made from high-quality materials, such as stainless steel, aluminum alloy, or high-performance engineering plastics. Additionally, pay attention to the surface treatment and protective coating of the product to enhance its corrosion and wear resistance.

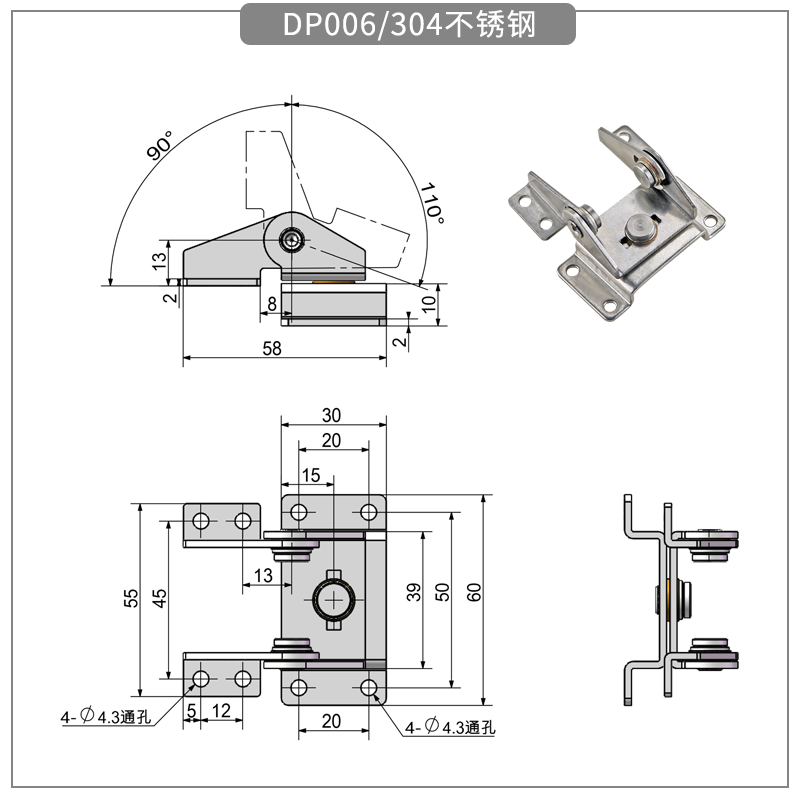

Mounting Method and Size

Ensure that the mounting method of the dual-axis torque hinge aligns with the structure of your equipment or product, and that it is correctly sized for seamless installation and optimal functioning in the mounting position.

Brand and After-Sales Service

Choosing a well-known brand of Twin Axis Torque Hinge typically ensures product quality and performance. Additionally, it is important to familiarize yourself with the brand’s after-sales service policy to address any issues promptly.

Installation and Commissioning

Preparation Before Installation

Read the installation instructions of the product carefully and prepare the required installation tools and accessories.

Clean the installation location to ensure that the surface is flat, clean, and free of oil and debris.

Installation Steps

Follow the instructions in the installation manual to properly install the components of the dual-axis torque hinge onto the equipment or product. Pay attention to the installation sequence and direction to ensure smooth rotation of the shafts.

Use appropriate screws and fasteners to securely attach the hinge in place during installation to prevent it from becoming loose.

Commissioning

After the installation is completed, debug the torque according to the actual demand. Typically, the torque can be adjusted by manipulating screws, nuts, or other adjusting devices.

Repeatedly test the opening and closing actions of the components, check whether the staying position and strength meet the requirements, and if necessary, carry out further fine-tuning.

V. Maintenance and Care

Regular cleaning

Use a clean, wet cloth or soft brush to remove dust and debris from the hinge surface. Avoid using corrosive cleaners.

Lubrication

According to the frequency of use and environmental conditions, add the appropriate amount of lubricating oil or grease regularly to the shaft and movable parts of the hinge to reduce friction and wear.

Inspection and Adjustment

Regularly check if the fixed parts of the hinge are loose, if the rotation of the shaft is smooth, and if the torque is normal. If any issues are identified, promptly make adjustments and repairs.

VI. Common Problems and Solutions

Insufficient torque

Check whether the torque adjusting device is set correctly. If necessary, adjust the torque accordingly.

Check whether the hinge is worn or damaged. If necessary, replace the hinge.

The opening and closing are not smooth.

Clean the shaft and moving parts of the hinge to remove dirt and debris.

Check for improper installation or deformed parts, and adjust or repair them accordingly.

Excessive noise

Add lubricating oil or grease to the hinge to reduce friction noise.

Check whether there are loose or worn parts, and tighten or replace them.

In conclusion, the dual-axis torque hinge is a robust and commonly utilized type of hinge. A comprehensive grasp of its features and requirements, along with correct operation and maintenance during purchase, installation, commissioning, and use, can guarantee its optimal performance and offer dependable opening and closing solutions for your equipment and products.

We hope that the above tips will be helpful to you and make you more comfortable using Twin Axis Torque Hinge!

logo

logo