In the industrial field, heavy duty industrial door hinges play a crucial role. Not only does it have to bear huge weight, but it also has to ensure the smooth opening and closing of the door and long-term stable operation. Proper selection of heavy duty industrial door hinges is essential to ensure the safe and efficient operation of industrial facilities. The following is a detailed guide to the purchase of heavy duty industrial door hinges.

First, understand the type of heavy-duty industrial door hinges

Ordinary hinges

This type of hinge has a simple structure and a relatively low price. It is suitable for general weight industrial doors, but may not be able to provide sufficient support for particularly heavy doors.

Heavy duty hinges

Specifically designed to withstand the weight of heavy industrial doors. Usually made of high-strength materials for greater load-bearing capacity and better durability.

Spring Hinges

With a spring mechanism that automatically closes the door when it is opened. Suitable for applications where automatic door closing is required, such as warehouse doors, workshop doors, etc.

Hydraulic Hinge

With hydraulic cushion device, it can realize the slow closing of the door and reduce the impact force when closing the door. It is very suitable for the occasions that need to open and close the door frequently and have requirements for closing speed.

Second, consider the weight and size of the door

Determine the weight of the door

Before purchasing heavy duty industrial door hinges, the first thing to do is to accurately measure the weight of the door. Different types of hinges can withstand different weights, the choice of hinges must ensure that its carrying capacity is greater than the actual weight of the door. Generally, you can refer to the product manual of the hinge or consult the manufacturer to determine the appropriate hinge model.

Consider the size of the door

The size of the door will also affect the choice of hinges. Larger sized doors require larger sized hinges to ensure the stability and balance of the door. At the same time, the installation position of the hinges also needs to be reasonably planned according to the size of the door to ensure that the door opens and closes smoothly.

Third, pay attention to the material of the hinge

Steel

Steel is a commonly used material for manufacturing heavy duty industrial door hinges, which has the advantages of high strength and corrosion resistance. The performance of different grades of steel varies. Generally speaking, the hinges made of high-strength alloy steel have better carrying capacity and durability.

Stainless steel

Stainless steel hinges have good corrosion resistance and are suitable for wet and corrosive environments. However, stainless steel is relatively costly and may not be as strong as some steels.

Cast Iron

Cast iron hinges are relatively inexpensive, but are heavier and less corrosion resistant. When choosing cast iron hinges, you need to consider its use environment and maintenance costs.

Check the quality and workmanship of hinges

Appearance quality

Check whether the surface of the hinge is smooth, no burr, no cracks and other defects. Good appearance quality can not only improve the beauty of the hinge, but also reflect the level of its manufacturing process.

Dimensional accuracy

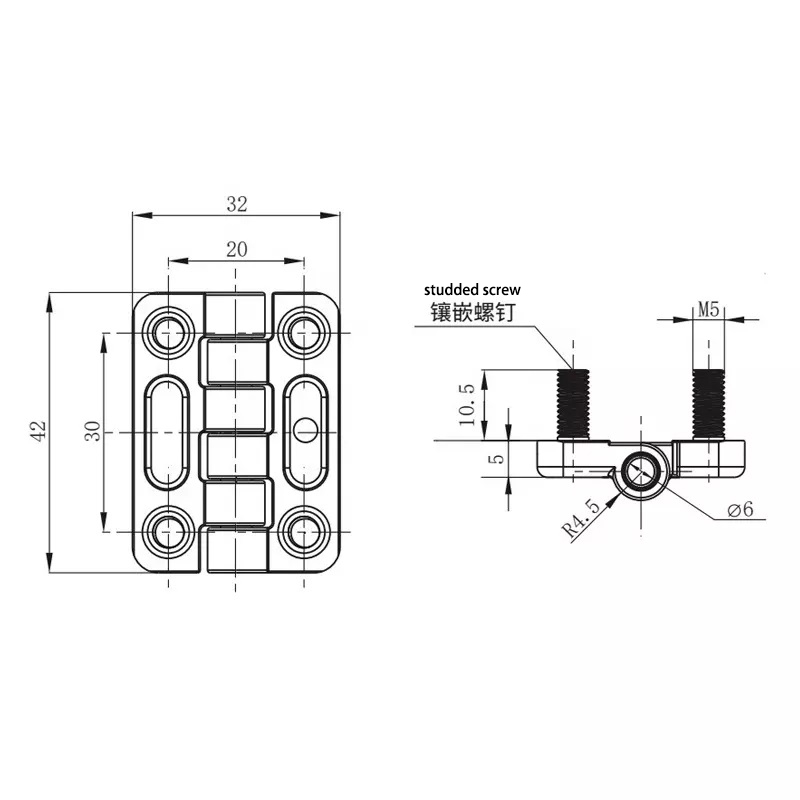

The dimensional accuracy of hinges directly affects the installation and use of the door. When purchasing, check whether the dimensions of the hinges meet the standard requirements, especially whether the position and size of the mounting holes are accurate.

Welding quality

For welded hinges, it is necessary to check whether the welded parts are firm, free of air holes, no slag and other defects. The quality of welding is directly related to the strength and durability of the hinge.

Surface treatment

Surface treatment can improve the corrosion resistance and aesthetics of hinges. Common surface treatment methods include galvanization, spraying, chrome plating and so on. Choose hinges with good quality and uniform surface treatment.

Fifth, consider the installation and maintenance of hinges

Installation

Heavy industrial door hinges can be installed in various ways, such as welding, bolting and so on. When choosing hinges, consider the structure and installation conditions of the door and choose the appropriate installation method. At the same time, it is necessary to ensure that the installation process is simple and fast to reduce the installation cost and time.

Ease of maintenance

Choosing hinges that are easy to maintain can reduce the maintenance cost at a later stage. For example, some hinges come with removable parts, which is convenient for repair and replacement. In addition, choose hinges with good lubrication performance to reduce wear and prolong service life.

Sixth, refer to the brand and reputation

Choose well-known brands (Haisepu)

Heavy-duty industrial door hinges from well-known brands usually have better quality and performance guarantees. These brands usually adopt advanced technology and strict quality control system in the production process to ensure the reliability and stability of the products.

Refer to user reputation

You can find out the actual usage effect of different brands and models of hinges by checking user reviews and consulting industry experts. Users’ word of mouth can provide you with valuable references and help you make a wiser choice.

Consider the price factor

Determine the budget

Before shopping for heavy duty industrial door hinges, determine your budget range. The price of hinges of different brands, models and materials varies greatly, so you have to choose the right product according to your actual needs and budget.

Cost-effective analysis

Don’t just focus on the price, but also consider the quality, performance, brand and other factors of the hinge to conduct a cost-effective analysis. Choosing cost-effective hinges can reduce purchasing costs while meeting the needs of use.

In short, the purchase of heavy duty industrial door hinges requires comprehensive consideration of a number of factors, including the weight and size of the door, the type of hinge, material, quality, installation and maintenance, brand and reputation, and price. Only by choosing the right hinges can we ensure the safe and stable operation of industrial doors and improve the productivity and safety of industrial facilities.

logo

logo