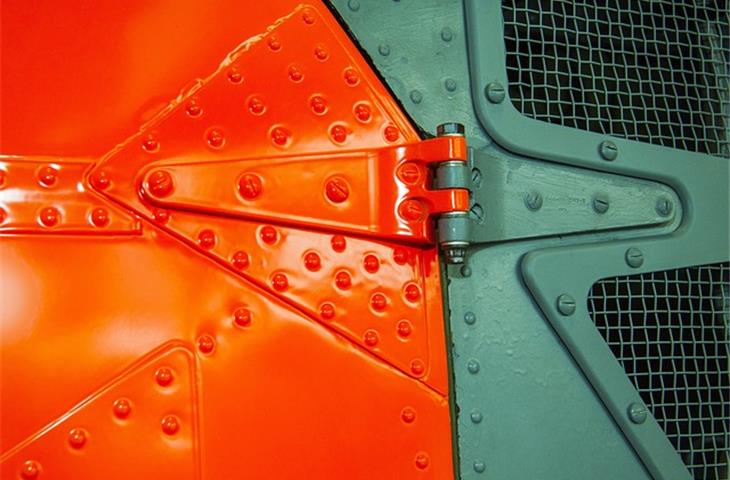

The pin hinge, an uncomplicated yet pioneering mechanical element, has emerged as a linchpin in numerous engineering domains. This multi-purpose joint enables rotatory motion, delivering stability and robustness in a compact form. Within this discourse, we shall delve into the complexities of pin hinges, scrutinize their applications, and examine the four pivotal imperatives propelling the progression of this inventive component.

I. Superior Durability and Load-Carrying Capacity

The initial imperative pertains to pin hinges exhibiting remarkable durability and load-carrying capacity. Given their deployment across diverse sectors including automotive, aerospace, and construction, these hinges must endure severe conditions and substantial loads. Engineers persistently seek novel materials and designs to augment the lifespan and fortitude of pin hinges.

II. Minimal Friction and Effortless Operation

The secondary demand pivots around diminishing friction and guaranteeing effortless operation. Pin hinges are often employed in apparatus necessitating precision and efficacy, such as robotics and medical instrumentation. By curbing friction, engineers can augment the overall performance and longevity of these devices.

III. Personalization and Agility

The third prerequisite is for adaptable and personalisable pin hinges. Numerous applications call for hinges adhering to distinctive specifications, such as shifts in sizes, angles, and materials. Engineers are pushing the envelope of design to fabricate pin hinges that can be configured to accommodate the precise prerequisites of their endeavours.

IV. Lean and Flat Design

The ultimate demand is for lightweight and flat pin hinges. In sectors like aerospace and robotics, weight is a paramount consideration. Engineers are ceaselessly endeavouring to diminish the size and weight of pin hinges whilst preserving their structural integrity and functionality.

Let us now scrutinise each of these imperatives and investigate how pin hinge innovations are addressing them.

Superior Durability and Load-Carrying Capacity

To satisfy the need for superior durability and load-carrying capacity, engineers are investigating new materials such as high-strength alloys and sophisticated composites. These materials can resist extreme temperatures, corrosion, and mechanical strain, thereby extending the lifespan of pin hinges in challenging environments.

Furthermore, ingenious designs, such as fortifying the hinge pin and incorporating shock-absorbent materials, are being formulated to amplify the load-carrying capacity of pin hinges. By incorporating these enhancements, engineers can craft more dependable and robust elements for assorted applications.

Minimal Friction and Effortless Operation

Diminishing friction in pin hinges is fundamental for applications that necessitate precision and efficacy. Engineers are carrying out research into varied methodologies, such as utilising self-lubricating materials and constructing bespoke coatings, to lessen friction and assure effortless operation.

On certain occasions, engineers are integrating ball bearings or roller bearings within the pin hinge to further decrease friction. These innovations not only boost the performance of the hinge but also contribute to the overall efficiency of the device in which it is incorporated.

Personalization and Agility

Adaptable and personalized pin hinges are vital for attaining the unique prerequisites of diverse applications. Engineers are harnessing advancements in 3D printing technology to fabricate custom pin hinges with specific dimensions and angles. This permits a tailored fit in apparatuses, ensuring optimal performance and functionality.

Additionally, the emergence of modular designs empowers engineers to conveniently replace or enhance pin hinges as required. This agility not only conserves time and resources but also encourages continual progress and innovation in the industry.

Lean and Flat Design

The pressing need for lightweight and flat pin hinges is especially palpable in the aerospace and robotics industries. Engineers are concentrating on diminishing the size and weight of pin hinges while preserving their structural integrity.

One methodology to accomplish this is through employing advanced manufacturing techniques, such as laser cutting and CNC machining, to devise intricate and lightweight hinge configurations. Additionally, integrating hollow pins or utilizing lightweight materials like titanium can aid in reducing the overall weight of the pin hinge.

In conclusion, the pin hinge has evolved into a pivotal component in contemporary engineering applications. By addressing the demands for superior durability, minimal friction, personalization, and lightweight design, engineers are relentlessly pushing the frontiers of pin hinge innovation. Consequently, these advancements are culminating in more dependable, efficient, and versatile mechanical solutions across a myriad of industries.

logo

logo